Auwell

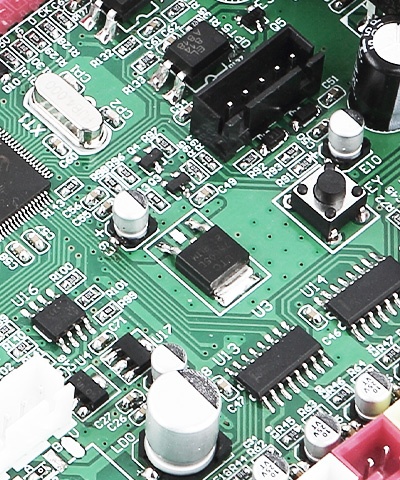

Auwell is an Electronic Manufacturing service (EMS)provider,which provides with a wide range of products and services in the fields of SMT assembly ,through hole assembly ,PCB assembly ,system assembly ,box building, cable assembly ,tooling design ,and also,Auwell offers outsourcing solutions for the development and manufactures of electronic assemblies and complete devices and systems.

Auwell PCBA assembly capabilities including:

Surface mounted assembly

· 5- high speed assembly lines

· Parallel Placer & T2 Placer from FUJI&SIMENS

· Chips, SOP,PLCCs,TQFPs,PQFPs,TSOPs. SOICs, QFPs, BGAs, QFNs, AL Caps, Connectors, Odd Form

· Components from 01005 to 150mm on 8-108mm Tape or Waffle Trays

· Acquisition and evaluation of the process steps in quality data management (Online SPC)

· Online traceability of production steps, component batches and test data at assembly level

· Online&Offline Feeder Setup

· Heller& ERSA reflow Ovens

· Mirtec MV-6DL online AOIs

· Mirtec MS- 11E 3D Solder Paste Inspection (SPI)

· Solder paste printing in screen printing process

· SMD assembly of printed circuit boards

· 3D solder paste inspection

· Automatic optical inspection(AOI)

· Stencil Washer

· In-House Q-Corporation Tape & Reel

· Panelized :small boards are panelized for efficency in bare board fabrication, as well as the PCB assembly process.

Through hole assembly

Many high power, high reliability, and legacy products continue to be built with through hole components and Auwell will continue to serve these customers with Automated Axial Insertion, Hand Assembly, Wave Soldering, Selective Soldering, and Hand Soldering.

· 5-automatic plug-in line &3-Semi automatic plug-in line

· Customer Focused Production Cells

· Automatic Terminal Insertion

· Custom Lead Forming Equipment

· Free Wave Solder

· Printed circuit board assembly

· Manual soldering according to IPC A-610

· Prototypes and very small series under serial production conditions

· Laser marking /labeling of printed circuit boards with unique serial number

· Design Fixture capability

· Design programming fixture capability

· Depaneling Press

· YB1608A In-Line Continuous Depaneler

Testing

With products becoming more complicated every day, testing prior to shipment assists us in ensuring our high quality levels. We employ several testing strategies to meet your needs and budget

· 2-automatic ICT&FCT testing line

· Semi-automatic ICT &FCT tester

· Continuity / Isolation

· Hi-Pot

· EMI/EMC test

· Salt spray test

· Constant temperature and humidity test

· RoHS test

· Automatic optical inspection(AOI)

· 100% visual inspection

· Sample In-Process Verification

· Programming of JTAG, Flash & EEPROM Devices

· Analogue and digital functional test

· PC based tester development

· Run-in/burn-in test

· Cable test

· RF test

· Systems test

· Performance Data Logging/Test Reporting

Capabilities

Product

Contact Us

Contact name: Owenly lee

Phone: +86-0755-23049300

E-mail: owenlylee@bandarytech.com

Address: 2nd Floor A-Building A Bao Industry Park, No.160 Luyuan Road, Keyuancheng, Tangxia Town Dongguan City, China